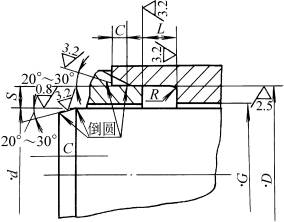

d | S | D |

| C ≥ | R ≤ | ||

L1 | L2 | L3 | |||||

6 | 4 | 14 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

8 | 4 | 16 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

10 | 4 | 18 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

5 | 20 | — | 8 | 16 | 2.5 | ||

12 | 4 | 20 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

5 | 22 | — | 8 | 16 | 2.5 | ||

14 | 4 | 22 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

5 | 24 | — | 8 | 16 | 2.5 | ||

16 | 4 | 24 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

5 | 26 | — | 8 | 16 | 2.5 | ||

18 | 4 | 26 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

5 | 28 | — | 8 | 16 | 2.5 | ||

20 | 4 | 28 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

5 | 30 | — | 8 | 16 | 2.5 | ||

22 | 4 | 30 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

5 | 32 | — | 8 | 16 | 2.5 | ||

25 | 4 | 33 | 5.0 | 6.3 | 14.5 | 2 | 0.3 |

5 | 35 | — | 8 | 16 | 2.5 | ||

28 | 5 | 38 | 6.3 | 8 | 16 | 2.5 | 0.3 |

7.5 | 43 | — | 12.5 | 25 | 4 | 0.4 | |

32 | 5 | 42 | 6.3 | 8 | 16 | 2.5 | 0.3 |

7.5 | 47 | — | 12.5 | 25 | 4 | 0.4 | |

36 | 5 | 46 | 6.3 | 8 | 16 | 2.5 | 0.3 |

7.5 | 51 | — | 12.5 | 25 | 4 | 0.4 | |

40 | 5 | 50 | 6.3 | 8 | 16 | 2.5 | 0.3 |

7.5 | 55 | — | 12.5 | 25 | 4 | 0.4 | |

45 | 5 | 55 | 6.3 | 8 | 16 | 2.5 | 0.3 |

7.5 | 60 | — | 12.5 | 25 | 4 | 0.4 | |

50 | 5 | 60 | 6.3 | 8 | 16 | 2.5 | 0.3 |

7.5 | 65 | — | 12.5 | 25 | 4 | 0.4 | |

56 | 7.5 | 71 | 9.5 | 12.5 | 25 | 4 | 0.4 |

10 | 76 | — | 16 | 32 | 5 | 0.6 | |

63 | 7.5 | 78 | 9.5 | 12.5 | 25 | 4 | 0.4 |

10 | 83 | — | 16 | 32 | 5 | 0.6 | |

70 | 7.5 | 85 | 9.5 | 12.5 | 25 | 4 | 0.4 |

10 | 90 | — | 16 | 32 | 5 | 0.6 | |

80 | 7.5 | 95 | 9.5 | 12.5 | 25 | 4 | 0.4 |

10 | 100 | — | 16 | 32 | 5 | 0.6 | |

90 | 7.5 | 105 | 9.5 | 12.5 | 25 | 4 | 0.4 |

10 | 110 | — | 16 | 32 | 5 | 0.6 | |

100 | 10 | 120 | 12.5 | 16 | 32 | 5 | 0.6 |

12.5 | 125 | — | 20 | 40 | 6.5 | 0.8 | |

110 | 10 | 130 | 12.5 | 16 | 32 | 5 | 0.6 |

12.5 | 135 | — | 20 | 40 | 6.5 | 0.8 | |

125 | 10 | 145 | 12.5 | 16 | 32 | 5 | 0.6 |

12.5 | 150 | — | 20 | 40 | 6.5 | 0.8 | |

140 | 10 | 160 | 12.5 | 16 | 32 | 5 | 0.6 |

12.5 | 165 | — | 20 | 40 | 6.5 | 0.8 | |

160 | 12.5 | 185 | 16 | 20 | 40 | 6.5 | 0.8 |

15 | 190 | — | 25 | 50 | 7.5 | ||

180 | 12.5 | 205 | 16 | 20 | 40 | 6.5 | 0.8 |

15 | 210 | — | 25 | 50 | 7.5 | ||

200 | 12.5 | 225 | 16 | 20 | 40 | 6.5 | 0.8 |

15 | 230 | — | 25 | 50 | 7.5 | ||

220 | 15 | 250 | 20 | 25 | 50 | 7.5 | 0.8 |

250 | 15 | 280 | 20 | 25 | 50 | 7.5 | 0.8 |

280 | 15 | 310 | 20 | 25 | 50 | 7.5 | 0.8 |

320 | 20 | 360 | 25 | 32 | 63 | 10 | 1.0 |

360 | 20 | 400 | 25 | 32 | 63 | 10 | 1.0 |

注:滑动面公差配合推荐H9/f8,但在液压缸使用条件不苛刻的情况下,滑动面公差配合也可

采用H10/f9。

1;所有标注为智造资料网zl.fbzzw.cn的内容均为本站所有,版权均属本站所有,若您需要引用、转载,必须注明来源及原文链接即可,如涉及大面积转载,请来信告知,获取《授权协议》。

2;本网站图片,文字之类版权申明,因为网站可以由注册用户自行上传图片或文字,本网站无法鉴别所上传图片或文字的知识版权,如果侵犯,请及时通知我们,本网站将在第一时间及时删除,相关侵权责任均由相应上传用户自行承担。

内容投诉

智造资料网打造智能制造3D图纸下载,在线视频,软件下载,在线问答综合平台 » 液压缸活塞杆动密封沟槽型式、尺寸及公差(图文教程)